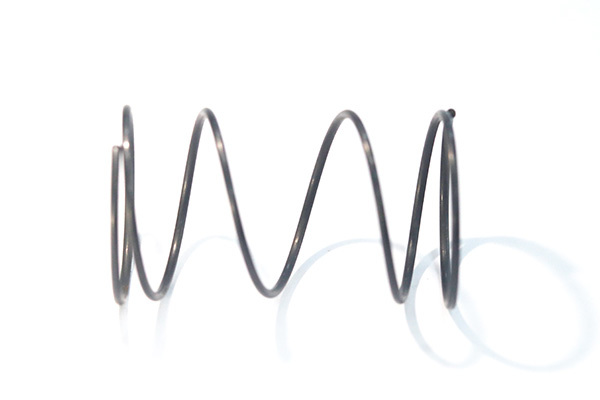

Cold-drawn spring steel wire (galvanized/bright)

Classification:

|

|

|

|

|

|

Precision Forming·High Durability·Dynamic Load Solutions

Engineered with controlled-temperature cold drawing process, our premium spring wire achieves superior fatigue resistance and dimensional stability through ultrafine grain structure, meeting stringent dynamic load requirements.

Core Advantages

Precision Tolerance: diameter tolerance±0.01mm

Extended Fatigue Life: 2 million cycles (typical), optimized grain orientation resists stress relaxation

Smooth Surface: steel surface Ra≤0.2μm reduces friction loss

Strength-Toughness Balance: tensile strength up to 3000MPa, elongation≥8%

Zinc Coating: optional electro-galvanized / Zn-Ni alloy layer (salt spray test≥240h)

Product Lines

1. Music Wire

Dynamic Applications: springs for automotive component, springs for home appliance auto-reset mechanisms

Performance Standards: elastic limitσ0.2≥1900 MPa, 40% improved impact resistance

2. Mechanical Spring Wire

Static Applications: furniture load-bearing springs, springs for construction machinery locking devices

Performance Standards: tensile strength 1600-2300MPa, international standard compliance

Galvanization Details:

Coating Types: electro-galvanized (standard), Zn-Ni alloy coating (high corrosion resistance)

Coating Thickness: 3-15μm customizable (standard anti-corrosion: 3-8μm, severe environments: 8-15μm)

Salt Spray Test Standards: ≥96h (standard coating), ≥240h (Zn-Ni alloy coating)

|

Name |

Diameter (mm) |

GB Standard |

EN Standard |

JIS Standard |

ASTM Standard |

|

Mechanical Spring Wire |

ф0.2-Φ12.0 |

GB/T4357-2009 DH |

EN 10270-1 DH |

JIS 3522 SWPB |

ASTM A228 |

|

Music Wire |

Φ0.15-Φ12.0 |

|

EN 10270-1 SH |

JIS 3521 SWC |

ASTM A227 Class I |

Technical Support

Material Control: carbon content 0.70%-1.00%, S/P impurities ≤0.015%

Customization Service: full specifications from φ0.15mm-φ12.0mm

Global Certifications: IATF 16949, RoHS/REACH compliant

Galvanization Line: fully automated electro-galvanized system, coating uniformity±1μm

Quality Testing: X-ray fluorescence thickness gauge (ISO 3497), salt spray test (ASTM B368)

Typical Application Case

Springs for New Energy Vehicle Suspension

Material: Music Wire SH-Grade

Performance: operating temperature -40℃~130℃, 15% weight reduction compared to traditional alloy springs

Key words: special steel wire, steel wire for textile equipment, steel wire for auto parts, steel wire for fishhook, steel wire for industrial brush, steel wire for hardware tools